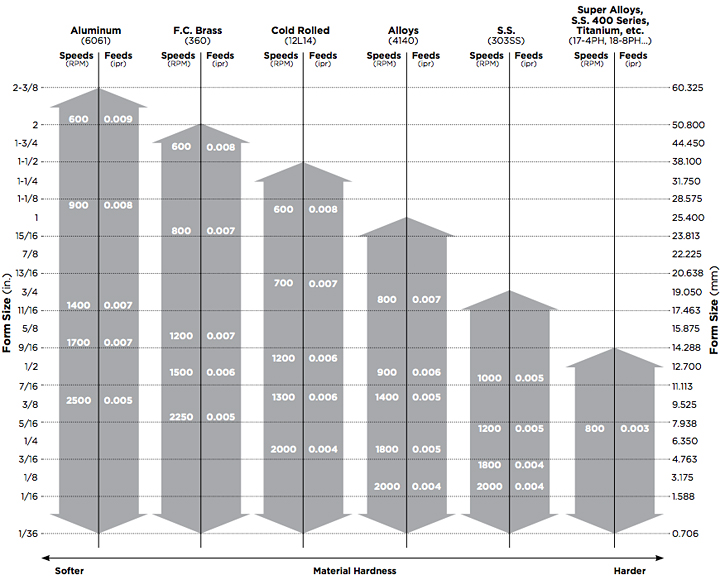

Speeds & Feeds

Rotary Broaching Recommendations by Common Workpiece Materials & Form Sizes

- This chart is provided as a reference to give starting point recommendations.

- Contact Slater Tools for the best solutions on your specific application.

- Larger external applications may require higher speeds or feeds.

- Slater Tools can also assist you with applications in plastics.

- In all materials, the smaller the broach diameter the lighter the feed should be.

- Lower feed rates give better workpiece finish. However, feed rates under 0.004 ipr can cause chips to lose flowing motion, creating excessive end loading pressure.

- Use rapid traverse when retracting off or out of a part.

- Mimimum and Maximum Conditions:

- Speeds 400-3500 RPM (revolutions per minute)

- Feeds 0.003-0.009 ipr (inches per revolution)